Network and PLC Upgrade for Process Evaporator

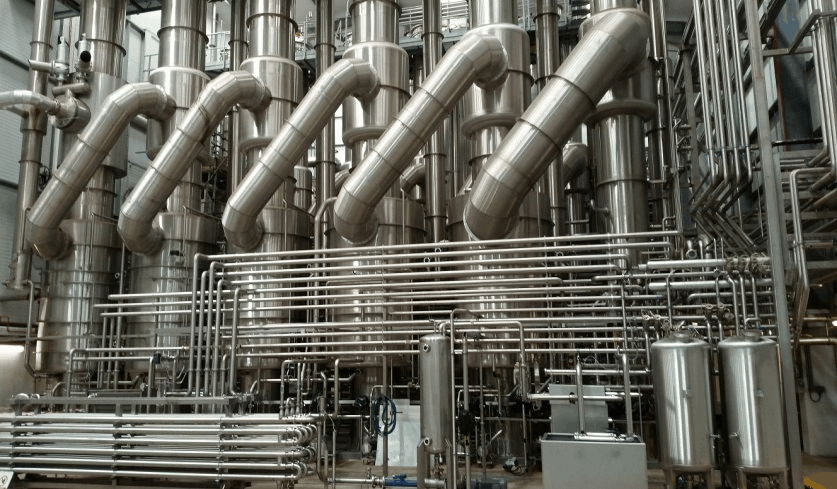

Heineken is one of UK’s most recognisable cider and beer brands, as well as the company behind some of the popular brands such as Strongbow and Foster’s. The company has a number of production plants in the country. Recently, Opensoft Systems was tasked to carry out a control systems upgrade on their process evaporator at their cider production plant that produces their cider portfolio, including Strongbow and Bulmers.

The Challenge

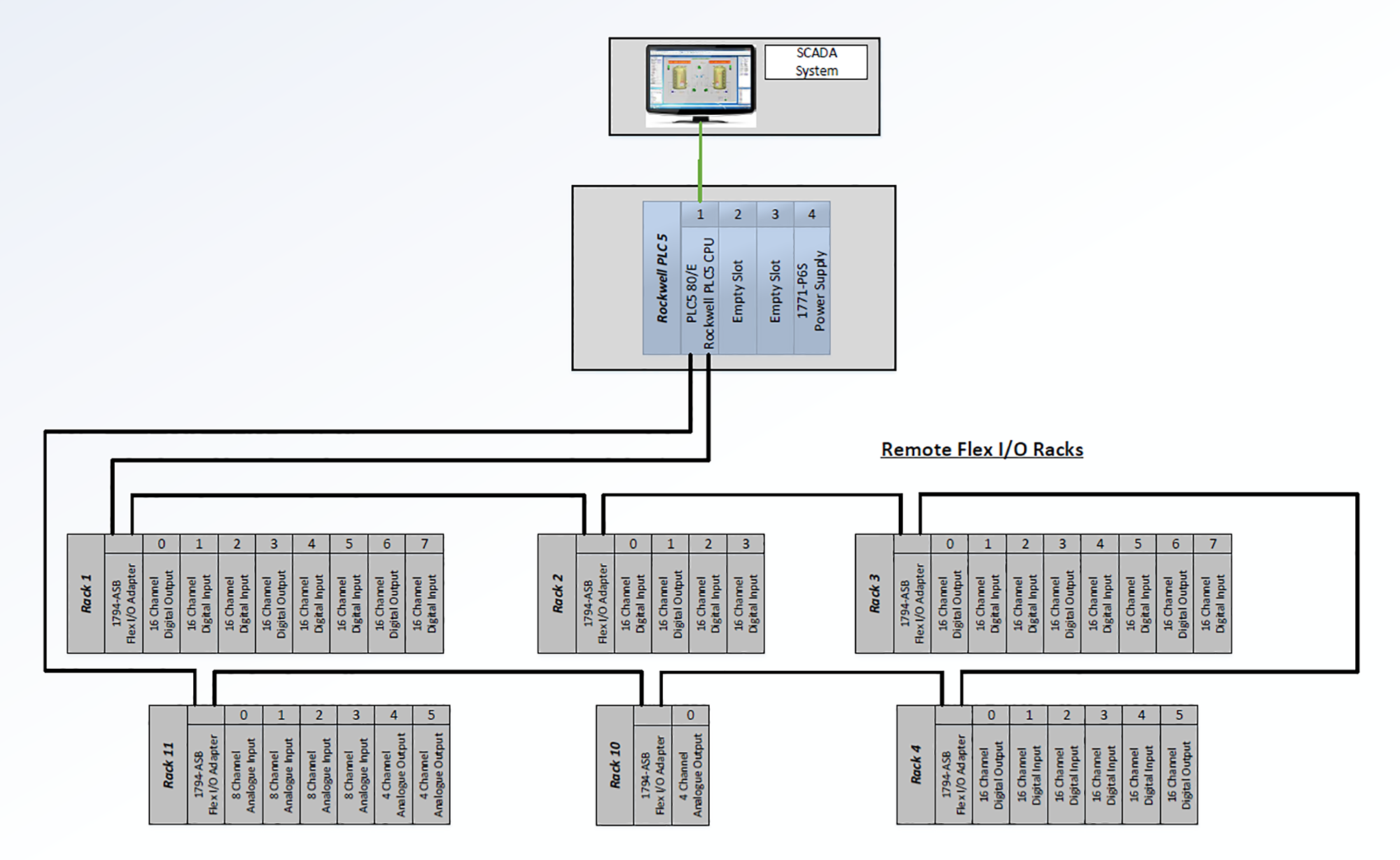

The Universal Beverages Ledbury manufacturing site has an important role in the production of Heineken beer and cider. The site processes some 130,000 tonnes of apples at the site every year. The control system across the plant consists of the main PLC communicating through a DeviceNet network to six other remote racks, and connected to a single SCADA system. The existing PLC is past its lifecycle and needs upgrading. The remote 1794-ASB flex I/O racks were also obsolete and unsupported and the DeviceNet network had been experiencing network faults.

The Proposal

To upgrade the plant’s system, Opensoft proposed to migrate their existing Rockwell PLC 5 series rack to a Rockwell Controllogix rack and replace the DeviceNet ring topology network with an Ethernet ring topology network.

The Solution

Before starting on the proposed solution, HEINEKEN and Opensoft Systems Engineering Teams worked together to develop a Functional Design Specification (FDS) to ensure that everyone involved is clear about their roles and responsibilities in the project. After HEINEKEN has signed off the FDS, the project was commissioned with minimal disruption to the production process. The new control system now provides stability to a critical part of the production process ensuring future supportability.

Technologies Used

Rockwell Control Logix 1756-L71 – 1794-ASB flex I/O racks

SCADA software

Client's Feedback

“We have now run all of the production processes and CIP recipes without many major problems and the machine is efficiently producing concentrate. All in all a very successful piece of work without any problems. Thanks to all of your colleagues at Opensoft who worked on this project.”

Site Automation Manager

Heineken