VIRTUAL SCADA & SERVER DEPLOYMENT

for Industrial Control Systems

Virtualising your Industrial Control System will:

- Reduce total ownership cost

- Reduced downtime

- Increase the life of your Industrial Control System

- Increase flexibility to change and implement continuous improvement

- Improve operation costs, which is the biggest payoff.

How a cheese manufacturing company achieved systems resilience with virtualisation.

The Background:

Our client is a manufacturer of award-winning cheese and some of the most recognisable brands of cheeses available in the market. They are one of the largest producers of cheddar in the UK.

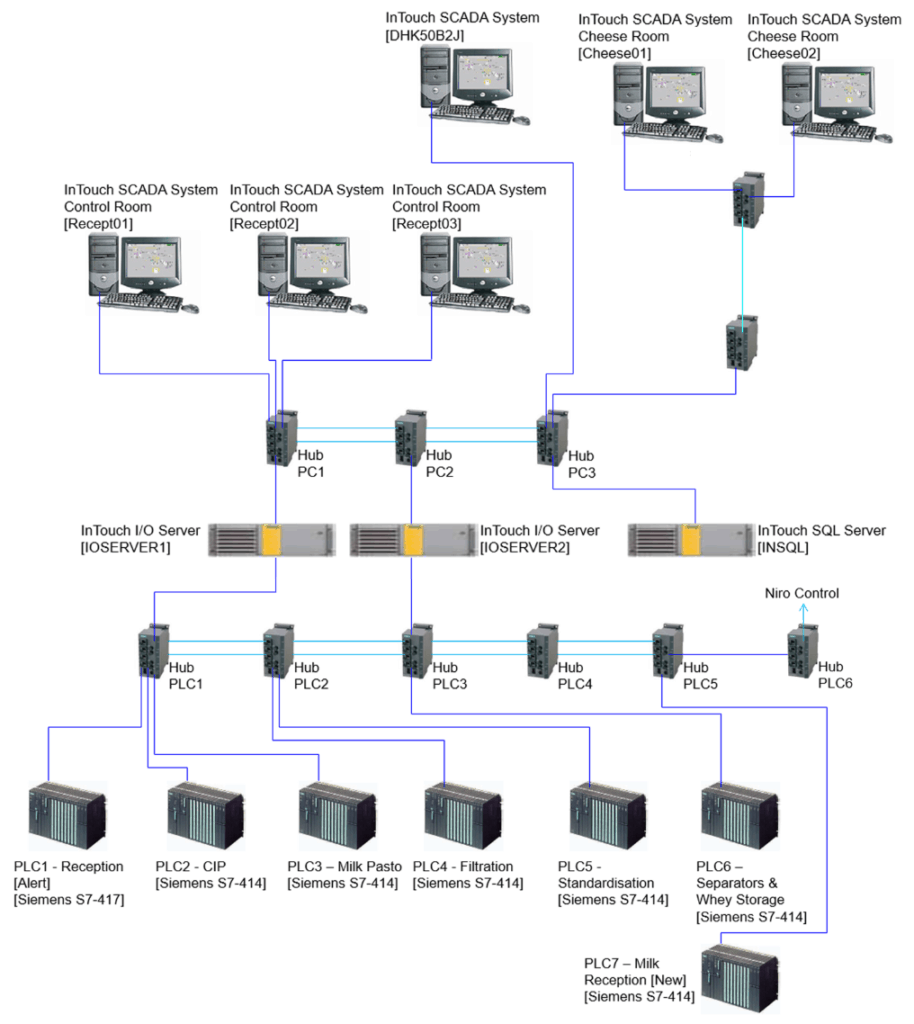

Our client’s site production system responsible for the dairy process was deployed over 15 years ago. Their existing InTouch SCADA is installed in a traditional PC located in the reception area and cheese production area. As the cheesemaking process involves heating cheese vats by steam, humidity is a constant challenge in the factory.

The Challenge:

The humidity is causing condensation on the plant floor. The constant damp in the factory is damaging their PC’s components, causing them to short-circuit and fail. When this happens, they lose their data, and they have to rebuild their system every time. Leaving their production line out of action, wasting their time, and skewing their production schedule.

Following several systems failures that disrupted their production, their group automation engineer approached Opensoft Systems to address the issue. One vital part of their brief is for Opensoft Systems to come up with a solution based on their current Wonderware InTouch platform and to factor in future expansion plans.

The Solution:

Following the initial consultation, we proposed the following solution:

- Take an image of their existing system and install it on a virtual machine server.

- Keep the virtual server in an air-conditioned room in a different location within the plant, where condensation is not a problem.

- Build active redundancy to increase system reliability

The Implementation:

The process was split into two phases. Phase 1 is virtualising their existing system. Opensoft Systems took a copy of our client’s existing system and upload them to the virtual machine server that is now located in a different area with controlled temperature.

In phase 2, we upgraded their InTouch SCADA in the virtual platform, which means we didn’t have to worry about compatibility issues.

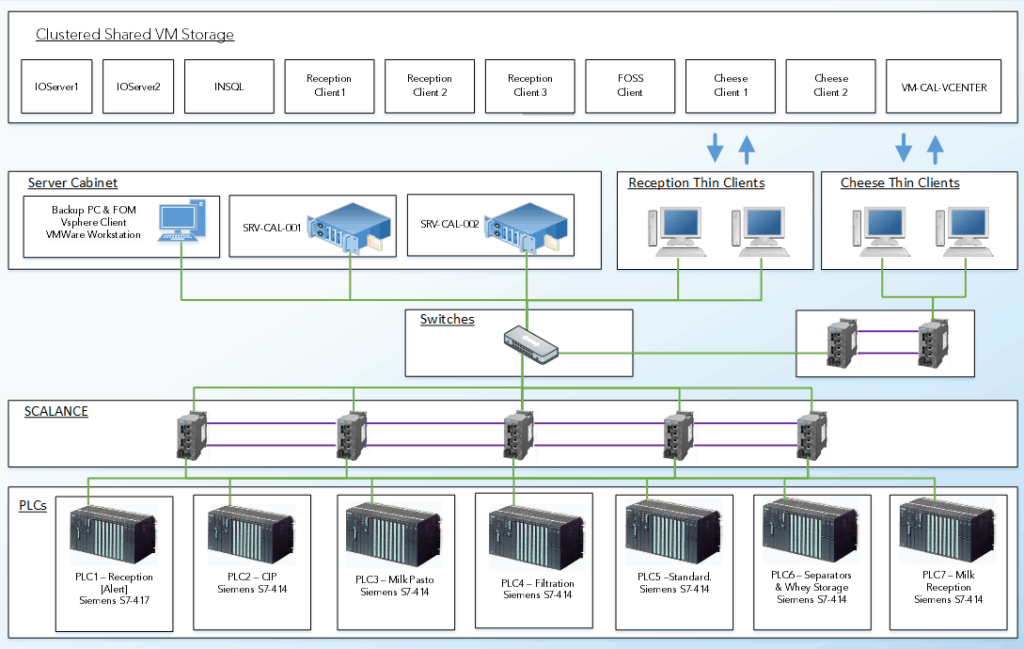

As their existing S7-400 PLCs are still in good order, we re-used them and upgraded the PLC communication to Ethernet to enable radio frequency detection with auto switch-over to the standby server in the event of system failure. This means that when one system fails, the virtual machines running on it will move to the other server and start automatically.

To remove the risk of local PC failure, we deployed thin client technology to access the server. As thin clients have no hard drive and operating system, they are resilient to dampness. And if they fail, they can be easily replaced without affecting the data.

The virtualised environment now provides fully automatic failover in case of systems failure.

This provides the plant with a redundant system that is extremely quick to rebuild when required. A fully built client can be configured as a master template and redeploy within minutes.

New systems architecture designed by Opensoft Systems

Client’s Feedback

‘Since the new system was installed, it has performed more smoothly with the added safeguard that our SCADA is now fully redundant. We can expand the system as required without unnecessary system build time. With thin clients, we don’t need extra PCs across the plant, which in the past, have become an additional maintenance overhead for us.

Group Automation Engineer