Batch Plant Legacy Control System Upgrade for World Class Glass Manufacturing Facility in Yorkshire

Our client is an award-winning, independently owned premium glass bottle manufacturer that designs, develops, and manufactures luxury glass packaging for the world’s finest brands.

They supply inspirational bespoke glass packaging available to the entire spirits industry, producing beautiful glass bottles for a range of iconic international brands whilst also supporting the very smallest craft producers.

Since January 2017 Opensoft Systems have been engaged with this client for Plant Automation Solutions and Support Services.

Project Drivers

- Improve the process and plant automation infrastructure

- Optimise the operational expenditure

- Increase the reliability & stability of control system infrastructure mainly, Rockwell and legacy SCADA systems

- Increase the plant automation system uptime

- Minimize the plant automation system downtime

- Reduce the operating cost through the best practices & benchmarking

- Performance improvement

- A scarcity of skilled competency and management of resources

Scope of Engagement

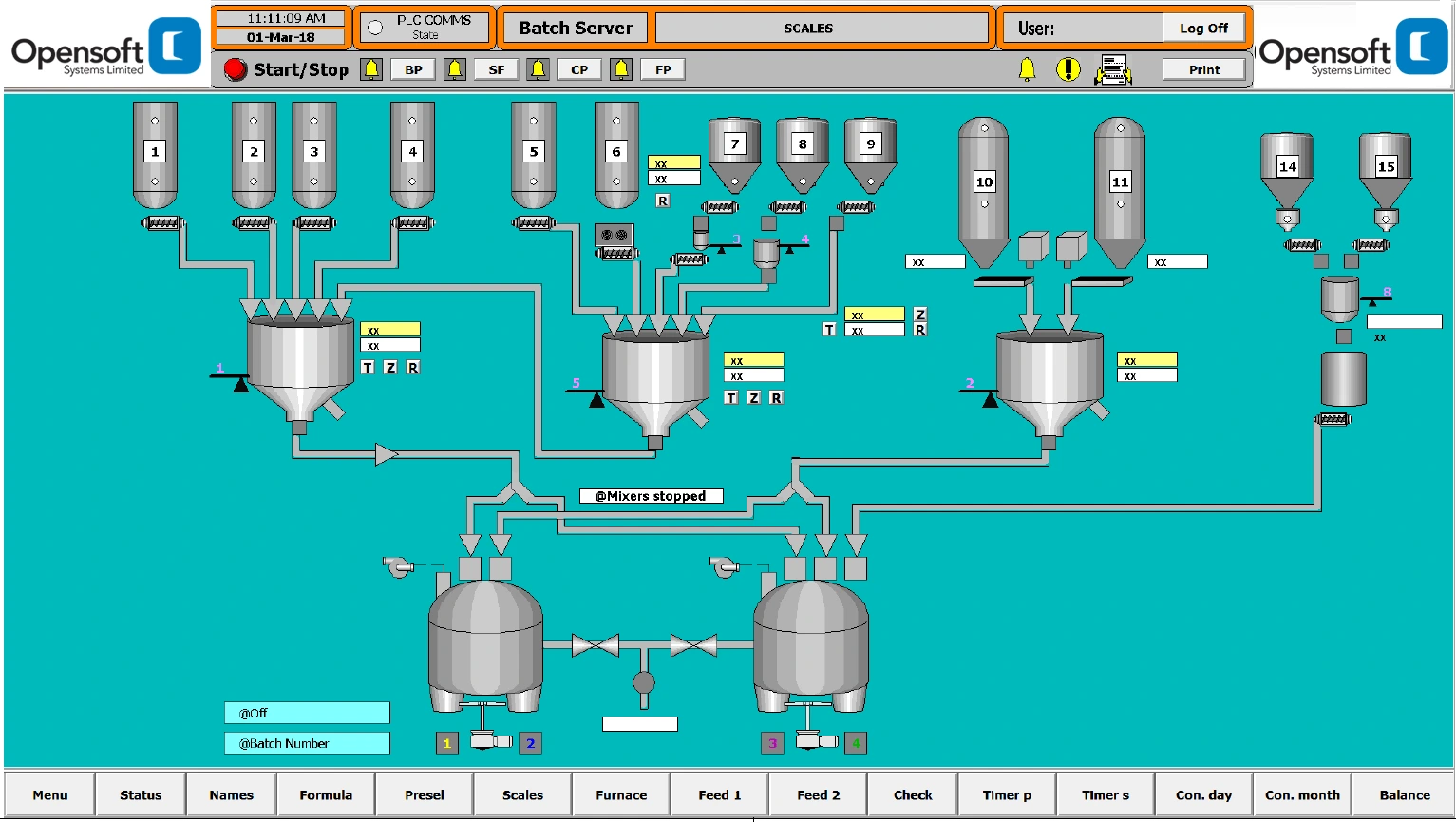

Plant automation solutions, consultancy, and systems integration including, SCADA replacement for Batch Plant process using new SCADA System.

- Existing Legacy SCADA replacement with new SCADA software

- Improvements to existing SCADA Graphics, Alarms, Trends, Reports, and Control

- An independent site-wide control system infrastructure Audit and Consultancy

- Proactive Control System Infrastructure Monitoring and Improvements

- SCADA training for the plant operational team

Value Proposition and Feedback

- Consultancy based solution and approach to achieve the project drivers and end objectives

- Understanding of the domain, data criticality and quality

- Proven track records to support the large scale implementation under the tight schedules

- Ability to integrate services at any stage of the client’s lifecycle

- Ability to develop customised solutions (retrofitting of Legacy infrastructure, predictive diagnostics, real time KPI dashboards and reports) to address the business needs using cutting edge technologies.

- Efficient & effective project execution of the SCADA upgrade with negligible plant downtime by running existing & proposed systems in parallel to ensure seamless transfer