The Need for Statistical Process Control (SPC)

Process variation increases the risk of defective products. If a faulty product makes it out of your factory, you are going to suffer. At best, it will dent your reputation. At worst, it will endanger the lives of your customers.

Implement robust Statistical Process Control (SPC) and ensure the quality of your manufacturing process and products by reducing process variation. A well-implemented SPC system has the following benefits:

- Marginal process variation

- Reduced manual operations

- Reduced production cost

- Real-time monitoring of quality trends

- Less faulty products

- Reduced human errors

SPC Audit by Opensoft Systems

If your organisation isn’t experienced or lacks adequate resources or solid systems to effectively implement and realise the full benefit of SPC, Opensoft Systems SPS consulting can be of value.

Our engineers and programmers are experienced in the planning and execution of the SPC process and related tools. Their experiences and expertise are gained through working with existing clients from various industries including Food & Drink, Energy from Waste, Pharmaceuticals, Heavy Equipment, Energy distribution, and Industrial Gas.

We can evaluate, advise, and offer direction to help you build an effective SPC system adapted to your business and quality challenges. If you have an existing SPC process that doesn’t meet your need, we will help you improve and streamline it.

Our SPC audit service provides you with a detailed audit of your existing SPC process. It will:

- Determine your unique SPC requirements.

- Give you a detailed inventory of your resources available for SPC.

- Determine your main areas of waste, ex: rework, scrap, excessive inspection time.

- Provide you with a thorough appraisal of your data collection and retention systems.

- Uncover barriers that are keeping you from using your data to its fullest.

- Outline our recommended course of action to align your SPC to your business goals, including identifying tools best suited to your process.

Opensoft Systems SPC Implementation Service

Armed with the result of our audit, you can choose us to implement your SPC system or invite other suppliers to quote for the project.

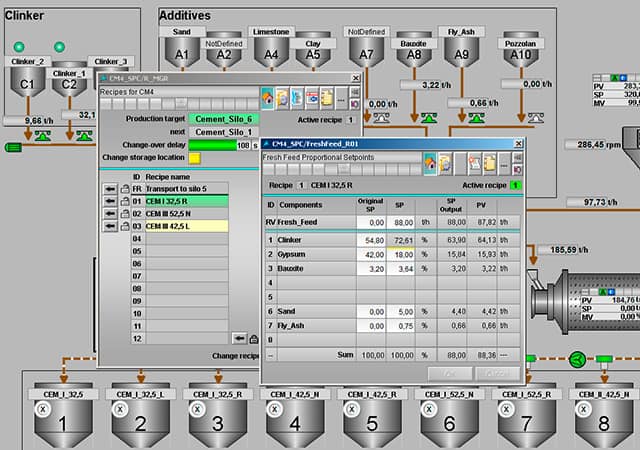

Our SPC implementation process starts with your functional design specification based on the information outlined in the SPC process audit. From this, we carry out a project development. This may include writing the program, setting up and configuring the SPC solutions, linking various machines or instrumentation, and other necessary actions identified during the SPC audit.