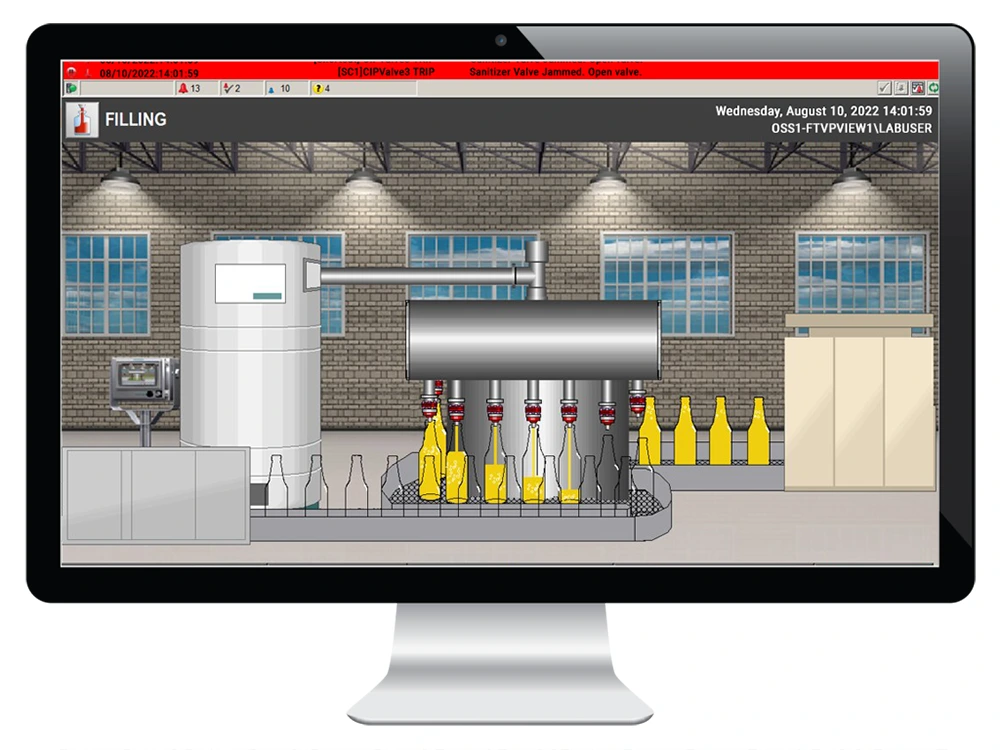

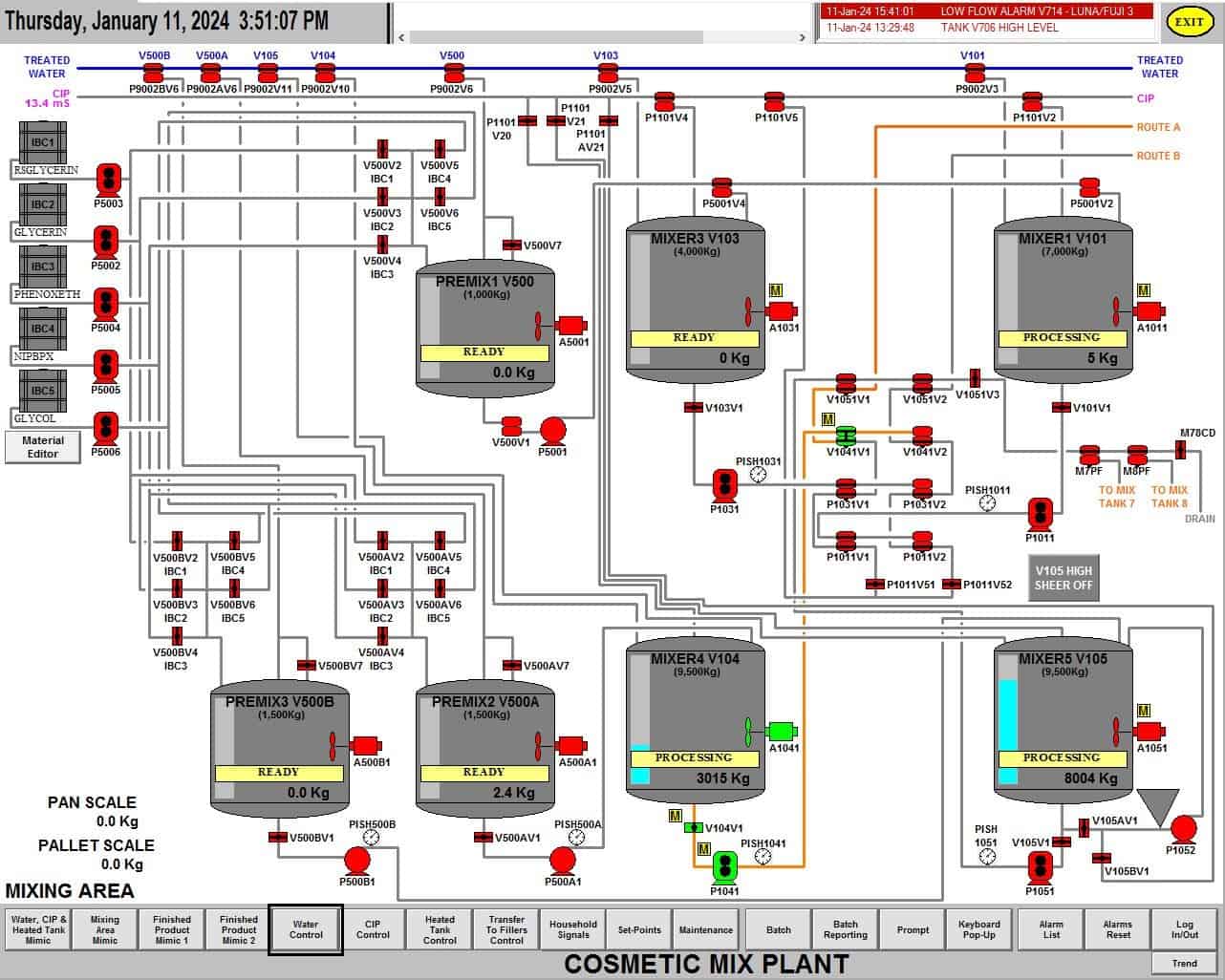

The key focus of our adapted training is to improve the confidence, troubleshooting & diagnostic skills of front line electrical / mechanical engineers & support staff.

Intended Audience

This course is for Rockwell / Allen Bradley FactoryTalk View – Machine Edition (FTView ME) HMI Technicians and Engineers who are responsible for installing, maintaining and fault finding on industrial automation plant systems which use Rockwell / Allen Bradley FactoryTalk View – Machine Edition & Site Edition (FTView ME) HMIs.

Software Used

Rockwell / Allen Bradley FactoryTalk View Machine Edition software.

Course Outline

This course introduces the Rockwell / Allen Bradley product family, a system overview of the FTView ME /SE which includes hardware and software components plus system configuration issues.

The course format is a combination of instruction and hands-on exercises. Demonstration exercises are included and allow delegates to practice tasks such as testing, debugging and using diagnostic tools.

Course Objectives

Recognise FTView ME / SE hardware and be able to replace modules when a fault occurs.

Be able to operate the FTView Machine Edition software to make it perform certain tasks.

Understand the basic concept of tags etc. and communications with the PLC.

Will be able to backup and restore the FTView Machine Edition HMI program when required.

Be able to perform system diagnostics when a problem occurs.

Brief Description

- Getting Started with FTView Machine Edition.

- Connecting Communication Cables.

- Creating an FTView Machine Edition Application File.

- Defining Communication Parameters.

- Creating a Tag Database.

- Creating Screen Text and Screen Selectors.

- Downloading an Application.

- Adding Controls to an FTView Machine Edition Application.

- Creating Messages.

- Creating a Report for an FTView Machine Edition Application.

- Troubleshooting an FTView Machine Edition Application.

- Generation of Documentation to Assist Fault Finding.