SCADA Connectivity for Materials Recovery Facility (MRF)

Our client is the UK’s largest family-owned supplier of integrated waste management and environmental services. Founded in 1929, they have developed a distinctive approach that has helped them to maintain a leading position within the waste industry. They are committed to quality of service, innovation and technical progress, together with a genuine and demonstrable concern for the environment.

Our client is the UK’s largest family-owned supplier of integrated waste management and environmental services. Founded in 1929, they have developed a distinctive approach that has helped them to maintain a leading position within the waste industry. They are committed to quality of service, innovation and technical progress, together with a genuine and demonstrable concern for the environment.

The Challenge

The Proposal

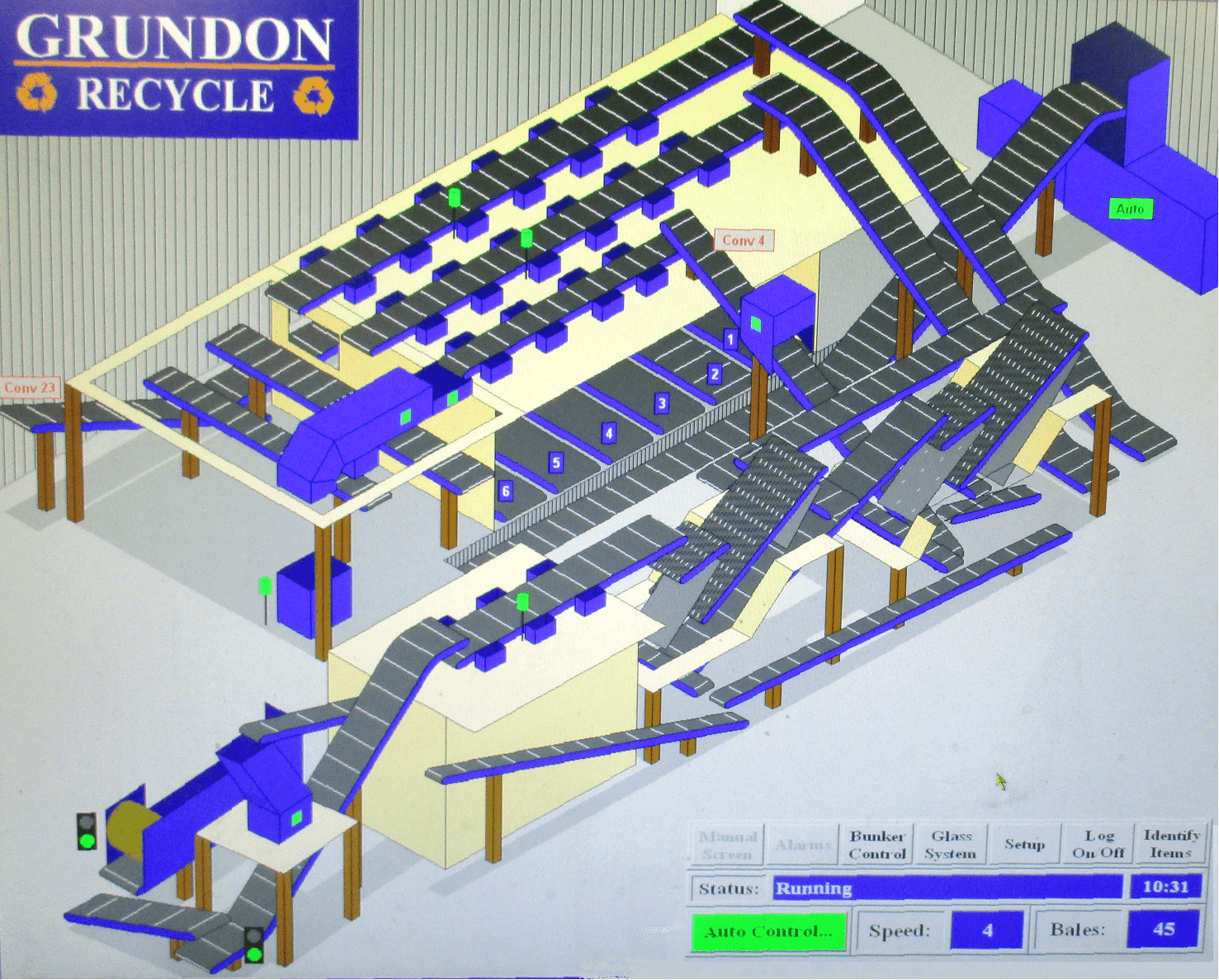

Following a discussion with the client, Opensoft Systems proposed a solution that involved installing a secondary Control Screen in the Bunker / Baler area linked directly to the Control Room Systems via RDP (Remote Desktop Protocol).

The Solution

Client's Feedback

“Opensoft Systems’ solution was implemented well and serves our needs perfectly. It enables the operation of the Baler smoothly and safely. Thanks to all involved.”

Site Electrical Engineering Manager

Grundon Waste Management